Isihlungi se-Diaphragm Physy Presor ngeBelt Conveyor ye-Wastewater Filtration Treatment

✧ Izici zomkhiqizo

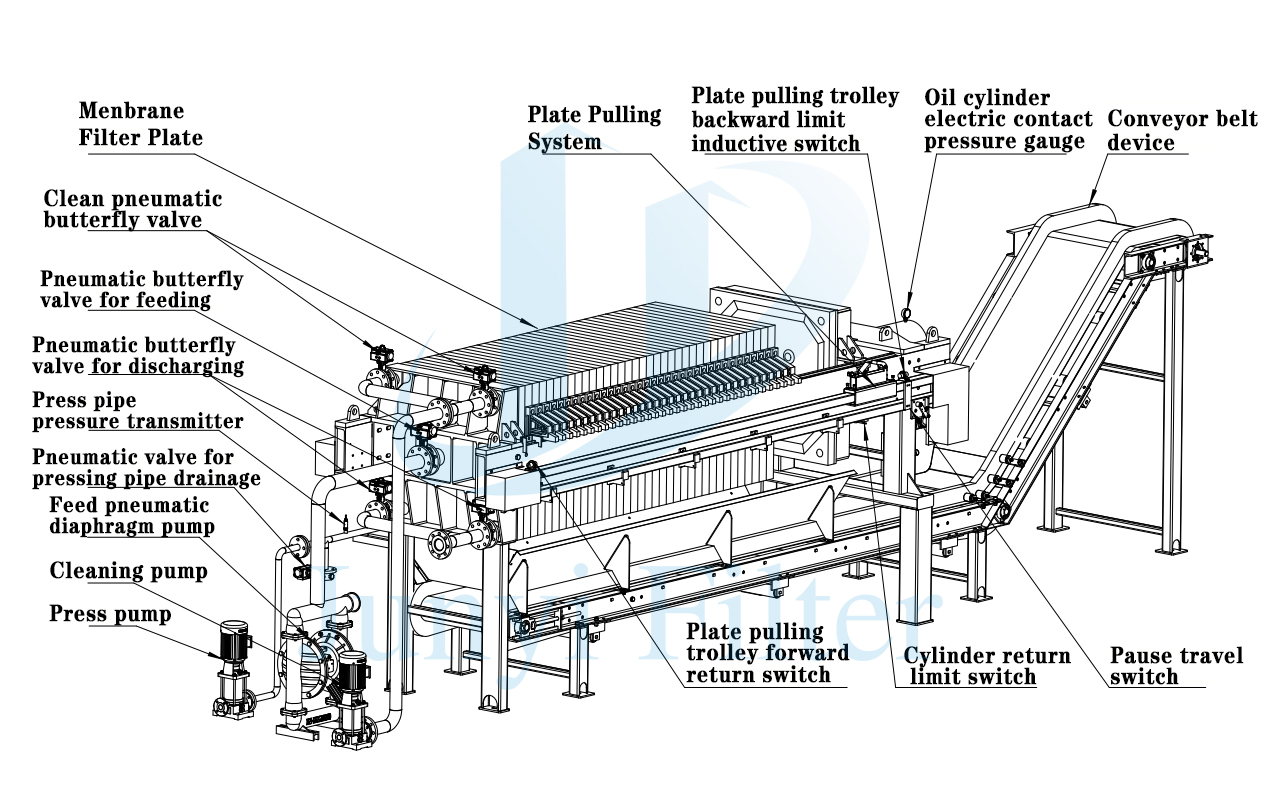

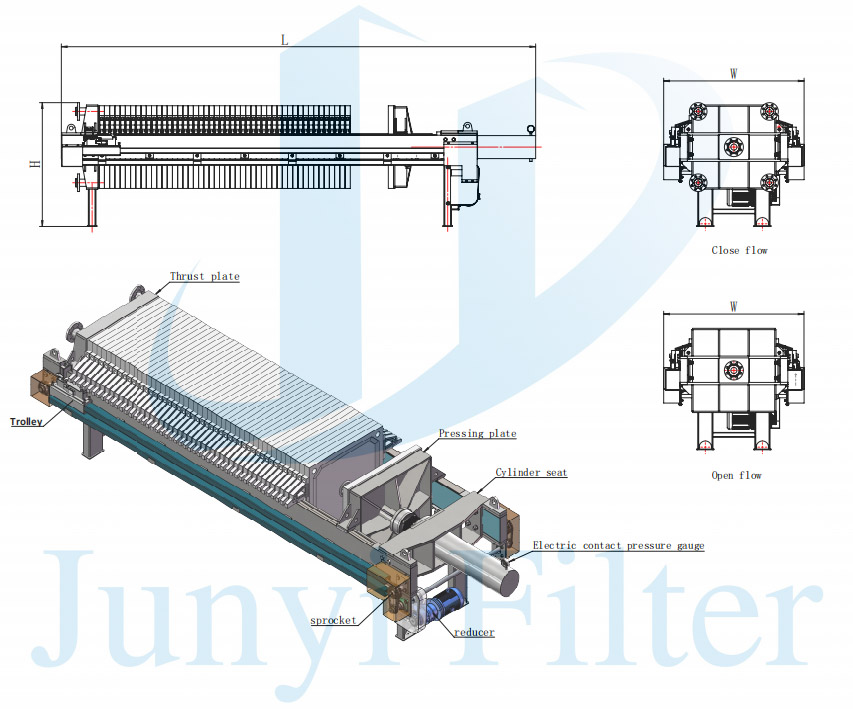

I-Diaphragm Finger Press Matching Equipment: I-Belt Conveyor, I-Liquid Recortiving System System Rinsing System, Isitoreji Se-PHPS, njll.

A-1. Ingcindezi yeFiltration: 0.8MPA; 1.0MPA; 1.3MPA; 1.6MPA. (Ngokuzithandela)

A-2. I-Diaphragm i-speezing ikhekhe ingcindezi: 1.0MPA; 1.3MPA; 1.6MPA. (Ngokuzithandela)

B, izinga lokushisa le-filltration: amazinga okushisa angama-45 ℃ / egumbini; 65-85 ℃ / izinga lokushisa eliphakeme. (Ngokuzithandela)

C-1. Indlela yokukhipha - Ukugeleza okuvulekile: Izimali ezidingekayo zidinga ukufakwa ngaphansi kwezinhlangothi zesobunxele nakwesokudla zepuleti ngalinye lokuhlunga, kanye nesinki esifanayo. Ukugeleza okuvulekile kusetshenziselwa uketshezi olungatholakali.

C-2. I-Liquid Exposet Method-Flow Flow: Ngaphansi kokuphela kokuphakelayo komshini wokuhlunga, kunamapayipi amakhulu aphezulu okuphuma, axhumene nethangi lokubuyisa uketshezi. Uma uketshezi ludinga ukutholakala, noma uma uketshezi luguquguqukayo, nge-snelly, oluvuthayo nokuqhuma nokuqhuma, kuyasetshenziswa ukuhamba okumnyama.

D-1. Ukukhetha kwendwangu yokuhlunga: I-PH yoketshezi inquma okuqukethwe kwendwangu yokuhlunga. I-PH1-5 iyindwangu yokuhlunga ye-acidic polyester, i-PH8-14 yindwangu yokuhlunga ye-alkaline polypropylene. Uketshezi lwe-viscous noma oluqinile lukhethwa ukukhetha indwangu yokuhlunga eqaphayo, futhi uketshezi olungelona olungabonakali noma oluqinile lukhethwe indwangu yokuhlunga ecacile.

D-2. Ukukhetha kwendwangu yokuhlunga: Uketshezi luhlukaniswe, futhi inombolo ehambisanayo ye-mesh ikhethiwe osayizi abahlukahlukene bezinhlayiya. Hlunga ngendwangu mesh ibanga le-100-1000 mesh. Ukuguqulwa kwe-micron ku-mesh (1Um = 15,000 Mesh --- emcabangweni).

Ukwelashwa okungaphezulu komhlaba kwe- Ingaphezulu lefreyimu yokuhlunga le-sandlosted kuqala, bese lifafazwa ngopende wokuqala wokuqala nolwala khona. Inani le-PH liyi-acid eqinile noma i-alkaline eqinile, ingaphezulu kohlaka lokuhlunga lwe-sandlosted, olufafazwe nge-primer, kanti ingaphezulu lisongwe ngensimbi engagqwali noma ngeplate ye-PP.

Ukusebenza kokucindezela kwe-F.Diaphragm Filter: Ukucindezela kwe-hydraulic okuzenzakalelayo; Hlunga ikhekhe ukugeza, ukudonsa okuzenzakalelayo kwepuleti; Hlola i-Plate Plate Deving Chutheni; Isistimu yokuhlunga yendwangu ezenzakalelayo. Sicela ungitshele ngomusa imisebenzi oyidingayo ngaphambi koku-oda.

G.filter ikhekhe ukugezathwa: lapho ama-solids adinga ukutholakala, ikhekhe lokuhlunga linamandla amakhulu noma i-alkali; Lapho ikhekhe lokuhlunga lidinga ukugezwa ngamanzi, sicela uthumele i-imeyili ukuze ubuze ngendlela yokugeza.

I-H.Filter Cindezela Ukudla Ukukhethwa kwepompo: isilinganiso esiqinile-uketshezi, i-acidity, izinga lokushisa kanye nezimpawu zoketshezi zihlukile, ngakho-ke kuyadingeka amaphampu ahluke kakhulu okuphakelayo. Sicela uthumele i-imeyili ukuze ubuze.

I.Automatic Belt Conlor Le divayisi ilungele iphrojekthi okungeyona elula ukwenza isisekelo sezisekelo. Kungalethwa ikhekhe endaweni ebekiwe, ezonciphisa umsebenzi omningi wezabasebenzi.

I-J.Automatic Dring Prey: I-Drip Tray ifakwe ngaphansi kwepuleti yokuhlunga cindezela. Ngesikhathi senqubo yokuhlunga, amathreyi epuleti amabili asesimweni esivaliwe, esingahola uketshezi lokudonsa ngesikhathi sokuhlunga kanye nokugeza izindwangu ku-Collector asemqondweni wamanzi. Ngemuva kohlunga, kwavulwa amathreyi amabili amabili epuleti ukukhipha ikhekhe.

K.the Filter Press Press Flusheng System: Ifakwe ngenhla komshini ophambili wesitimela sokuhlunga, futhi ifakwe umsebenzi wokuhamba nge-othomathikhi, futhi indwangu yokuhlunga ihlanjululwa ngamanzi aphezulu (36.0MPA) ngokushintsha i-valve. Kunezinhlobo ezimbili zezakhiwo ze-Rinsing: I-Single-Side Rinsing and Rinsing Esehlangothini elihlangene, lapho ukugcwala uhlangothi oluhlangene kunamabhulashi wokuhlanza okuhle. Ngomshini we-flap, amanzi acwebezelayo angavuselelwa futhi asetshenziswe kabusha ngemuva kokwelashwa ukonga izinsiza; Kuhlanganiswe nohlelo lwe-Diaphragm Cindezela uhlelo, lungathola okuqukethwe kwamanzi okuphansi; Uhlaka olubuthene, isakhiwo seCompact, kulula ukuhlukanisa kanye nokuhamba.

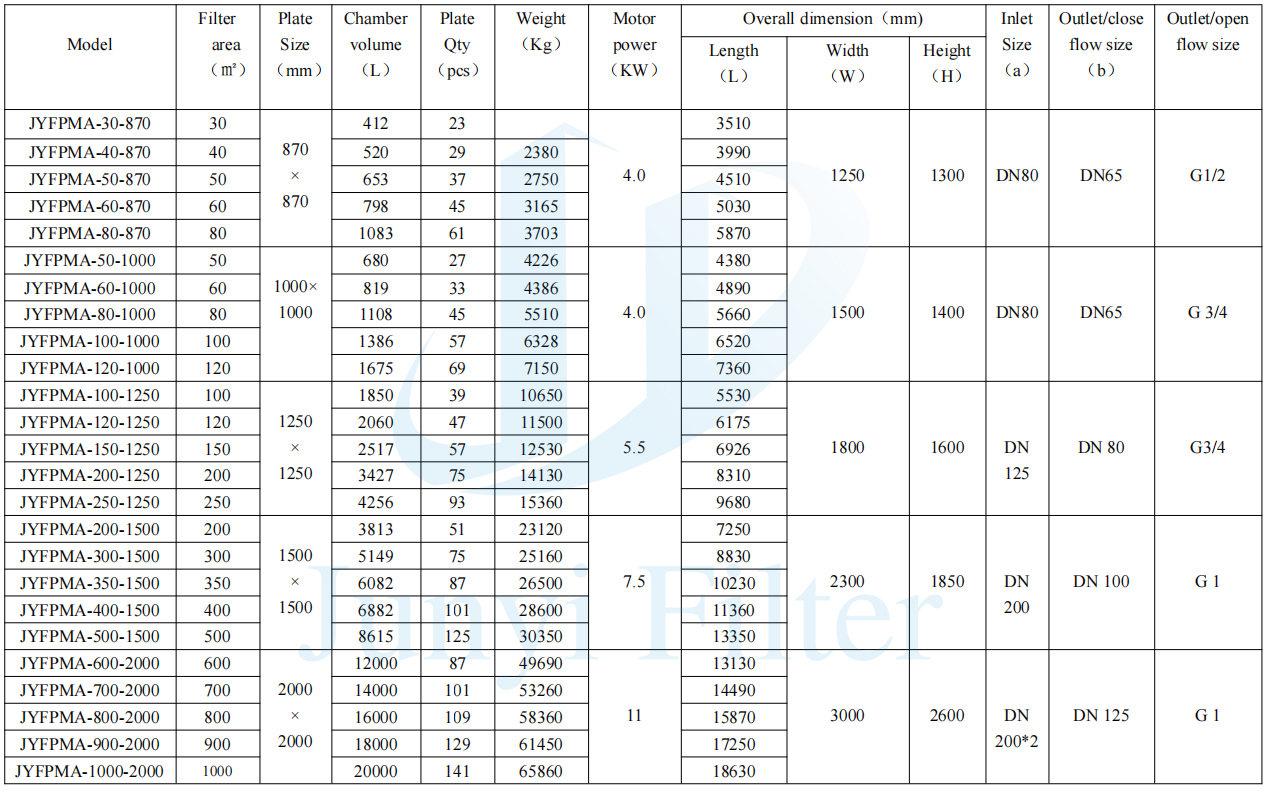

| Hlunga ukuholwa kwemodeli yokucindezela | |||||

| Igama eliwuketshezi | Isilinganiso esiqinile selitshe(%) | Amandla athile adonsela phansi weama-solids | Isimo sezinto ezibonakalayo | Inani le-PH | Ubukhulu obuqinile bezinhlayiyana(mesh) |

| Lokushisa (℃) | Ukubuyiselwa kweU-Liquid / Solids | Okuqukethwe kwamanzi kweIkhekhe lokuhlunga | Ukusebenzaamahora / usuku | Amandla / Usuku | Ukuthi uketsheziukuhwamuka noma cha |

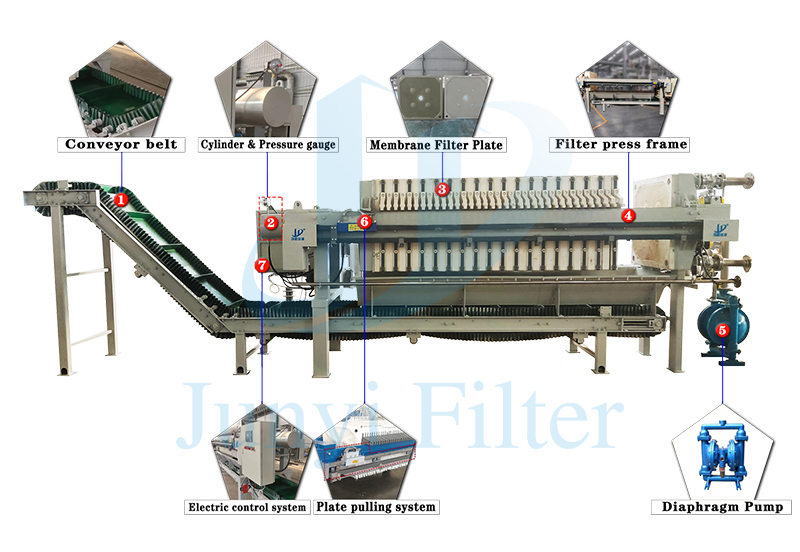

① Convevor BELT: Idivayisi isebenza esizeni somsebenzi okungekho lula ukwenza isisekelo. Kuyidivaysi esekelayo, efakwe ngaphansi kwamapuleti okuhlunga wesitimela sokuhlunga ukudlulisa ikhekhe lokuhlunga elikhishwe lapho ipuleti lokuhlunga lidonswa ngaphandle, futhi likwazi ukuthutha amakhekhe okuhlunga ekhasini eliqokiwe.

② Isilinda: Kuhlelo lwe-hydraulic, isilinda kawoyela sinesibopho sokuguqula amandla okucindezela e-liquid amandla okusebenza emandleni okuvuthayo, futhi aqhube umthwalo wokuvuselela okuqondile noma ukunyakaza okujikelezayo.

Ingcindezi Gauge: Kukhombisa ukucindezela kwamapuleti okucindezela kwesilinda kawoyela.

Ipuleti lokuhlunga le-membrane: Ipuleti lokuhlunga le-diaphragm lakhiwa ngamadada amabili nepuleti eliyisisekelo. I-medium yangaphandle (amanzi noma umoya ocindezelwe, njll.) Ungeniswa egumbini eliphakathi kwepuleti lomgogodla nolwelwesi ukwenza i-membrane bulge ukuze unciphise amakhekhe okuhlunga, wehlise okunye okuqukethwe kwamanzi kwamakhekhe okuhlunga. I-diaphragm yingxenye eyinhloko.

④ Hlunga Press Beam: lonke umshini wokuhlunga ugongolo luqoqeka futhi lufakwe amapuleti ensimbi Q345b. Ngemuva kokuqhuma kwe-centrifugal enesivinini esikhulu sokuqhuma nokuvimbela ukugqwala, kufafazwa ngama-coation alwa nokugqwala, futhi ingaphezulu lifafazwa ngezendlalelo ezintathu zopende we-resin.

⑤ I-Diaphragm Pump: I-QBY / QBK Series Pneumatic Diaphragm Pump iyiphampu yenoveli enkulu kakhulu eChina njengamanje. Ingakhipha futhi ithole zonke izinhlobo zotshwala obuzolololonga, njengoketshezi ngezinhlayiya, ukubukeka okuphezulu, ukuguquguquka okuvuthayo, okuqhumayo, ukulungiswa kwamafutha, ukululama kwamafutha e-oyela tanker, kanye nokuthululwa kwethangi lesikhashana. Izingxenye ze-Flow Pass zomzimba wepompo zenziwe ngensimbi engenasici, i-aluminium alloy, amapulasitiki we-cast kanye nobunjiniyela benziwe nge-nbr, i-polytetrafbesylene, futhi i-polytetrafbeerylene, kanye ne-polytetrafbesylene (F46) Ngokusho kwe-NBRIDS.QBy negesi ecindezelwe Umthombo, ngekhanda le-7m, ukuphakama okungu-0-90m, nokugeleza kuka-0.8-40 m3 / h, okungalungiswa ngokungathi lubi.

Singaphinde futhi sihlome ngezinye izinhlobo zepompo yokudla ngokuya ngezinto ezihlukile eziluhlaza.

Uhlelo lokudonsela ipuleti lwe-⑥: Uhlelo lokudonsa ipuleti oluzenzakalelayo luzimele, futhi abasebenzisi bangakhetha ukuthi bangayifaka noma cha. Ikwamukela amaketanga ensimbi angenasici kanye nama-stanlipulators wensimbi engagqwali.

I-⑦ System System Yokulawula Ugesi: Icala ikakhulukazi icala lokufafaza ngepulasitiki, izingxenye zikagesi zeSchneider, i-Nokia PLC, njll.

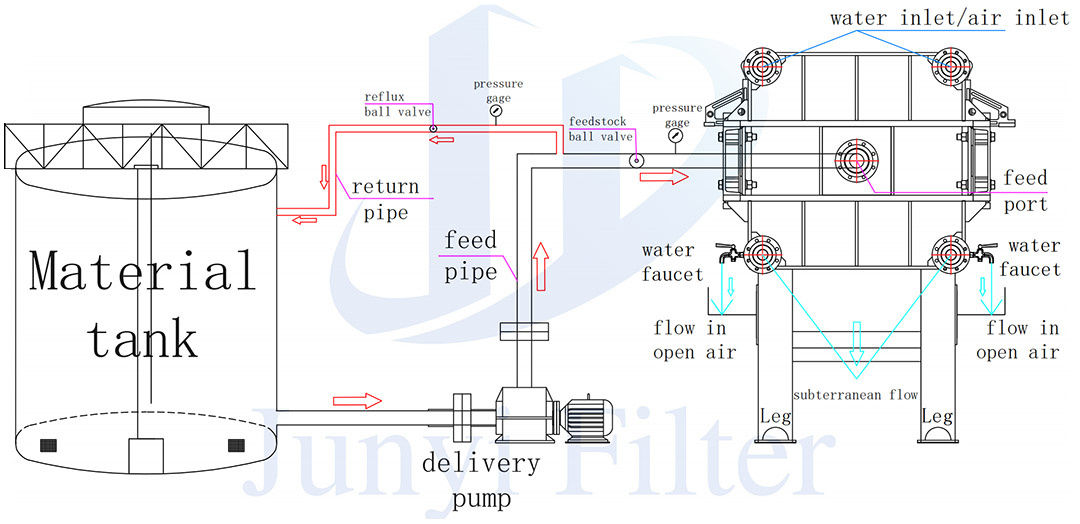

✧ Inqubo yokudla

✧ Izimboni zohlelo lokusebenza

Isetshenziswa kabanzi kwinqubo yokuhlukanisa eqinile ewuketshezi e-petroleum, amakhemikhali, i-dyestuf, ekhemisi, ukudla, usawoti, utshwala, imboni yokukhanya, ama-coal, ukudla, izindwangu, izimboni kanye nezinye izimboni.

✧ Ukuhlunga imiyalo yoku-oda

1. Bheka umhlahlandlela wokukhetha umshini wokuhlunga, isihlungi sokuhlunga ukubuka konke, imininingwane kanye namamodeli, khethaimodeli nemishini esekelayo ngokuya ngezidingo.

Isibonelo: Ukuthi ikhekhe lokuhlunga ligezwa noma cha, ngabe i-affaent ivulekile noma ivaliwe,Ukuthi ngabe i-rack imelana nokuphikisana noma cha, imodi yokusebenza, njll., Kufanele ichazwe kuinkontileka.

2. Ngokwezidingo ezikhethekile zamakhasimende, inkampani yethu ingaklama futhi ikhiqizeamamodeli okungewona ajwayelekile noma imikhiqizo eyenziwe ngezifiso.

I-3. Izithombe zomkhiqizo ezinikezwe kulo mbhalo zizobhekiswa kuphela. Uma kwenzeka ushintsho, thinangeke inikeze noma isiphi isaziso bese i-oda langempela lizonqoba.