I-Factory Supply Automatic Chamber Filter Cindezela Imboni Yezindwangu

✧ Izici Zomkhiqizo

A. Ingcindezi yokuhlunga<0.5Mpa

B. Izinga lokushisa lokuhlunga: 45℃/izinga lokushisa;80℃/ izinga lokushisa eliphezulu;100℃/ Izinga lokushisa eliphezulu.Isilinganiso sempahla eluhlaza yamapuleti okuhlunga okukhiqiza okushisa ahlukene akufani, futhi ubukhulu bamapuleti okuhlunga abufani.

C-1.Indlela yokukhipha - ukugeleza okuvulekile: Ompompi badinga ukufakwa ngaphansi kwezinhlangothi ezingakwesokunxele nezingakwesokudla zepuleti ngalinye lesihlungi, kanye nosinki ofanayo.Ukugeleza okuvulekile kusetshenziselwa uketshezi olungatholakali.

C-2.Ukuvala ukugeleza kwendlela yokukhipha uketshezi:Ngaphansi kokuphela kokuphakelayo komshini wokuhlunga, kunamapayipi amakhulu amabili aseduze aphumayo, axhunywe nethangi lokubuyisela uketshezi.Uma uketshezi ludinga ukubuyiswa, noma uma uketshezi luguquguquka, lunuka, luvutha futhi luqhuma, kusetshenziswa ukugeleza okumnyama.

D-1.Ukukhethwa kwempahla yendwangu yokuhlunga: I-pH yoketshezi inquma indwangu yendwangu yokuhlunga.I-PH1-5 iyindwangu yokuhlunga ye-polyester ene-acidic, i-PH8-14 iyindwangu yokuhlunga ye-alkaline polypropylene.I-viscous liquid noma eqinile ikhethwa ukukhetha indwangu yesihlungi se-twill, futhi uketshezi olungenayo i-viscous noma okuqinile kukhethwa indwangu yesihlungi esingenalutho.

D-2.Ukukhethwa kwemeshi yendwangu yokuhlunga: Uketshezi luyahlukaniswa, futhi inombolo yemeshi ehambisanayo ikhethwa osayizi abahlukene bezinhlayiyana eziqinile.Isihlungi se-mesh yendwangu ububanzi 100-1000 mesh.Ukuguqulwa kwe-Micron kuya kumanetha (1UM = 15,000 mesh---ngokombono).

E. Ukwelashwa kwendawo ye-rack: inani le-PH elingathathi hlangothi noma isisekelo se-asidi esibuthakathaka;Ingaphezulu lefreyimu yokucindezela isihlungi kuqala i-sandblasted, bese ifafazwa nge-primer kanye ne-anti-corrosion paint.Inani le-PH liyi-asidi eqinile noma i-alkaline eqinile, indawo engaphezulu yozimele wokucindezela isihlungi iqhunyiswa ngesihlabathi, ifuthwe nge-primer, futhi indawo engaphezulu igoqwe ngensimbi engagqwali noma ipuleti le-PP.

✧ Izimboni Zokusebenza

Uphethiloli, amakhemikhali, imithi, ushukela, ukudla, ukuwasha amalahle, uwoyela, ukuphrinta nokudaya, ukuphisa, izitsha zobumba, insimbi yezimayini, ukukhucululwa kwendle neminye imikhakha.

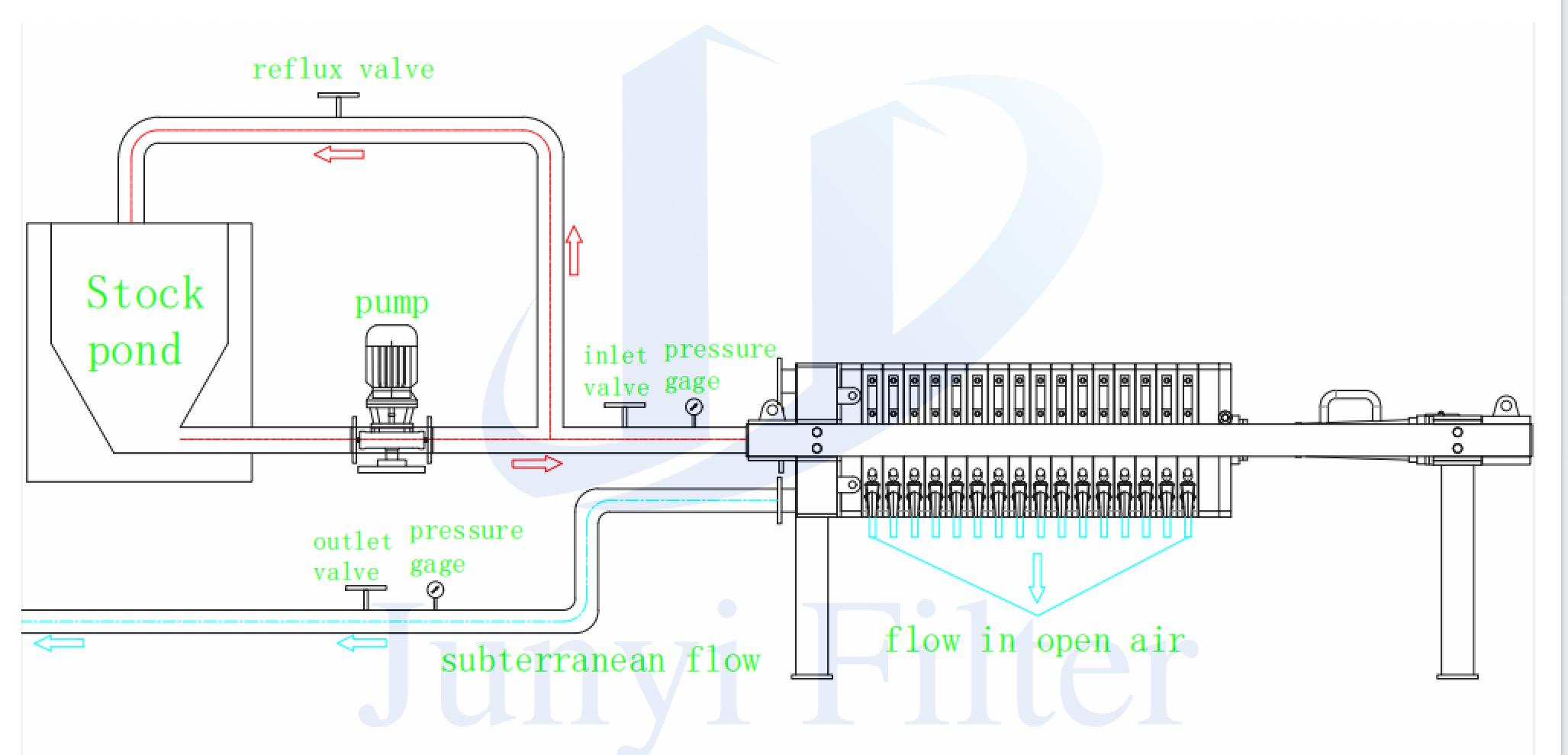

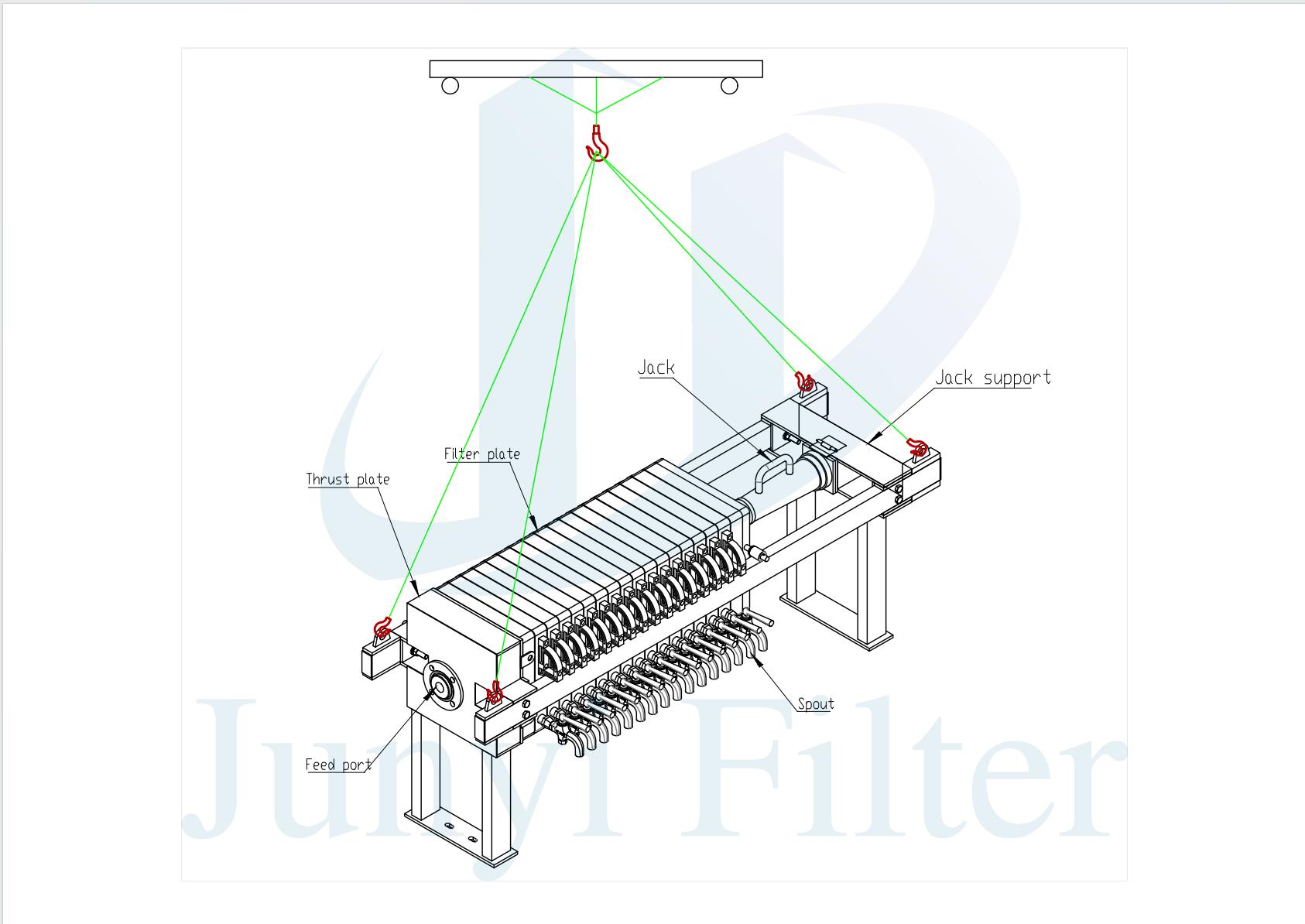

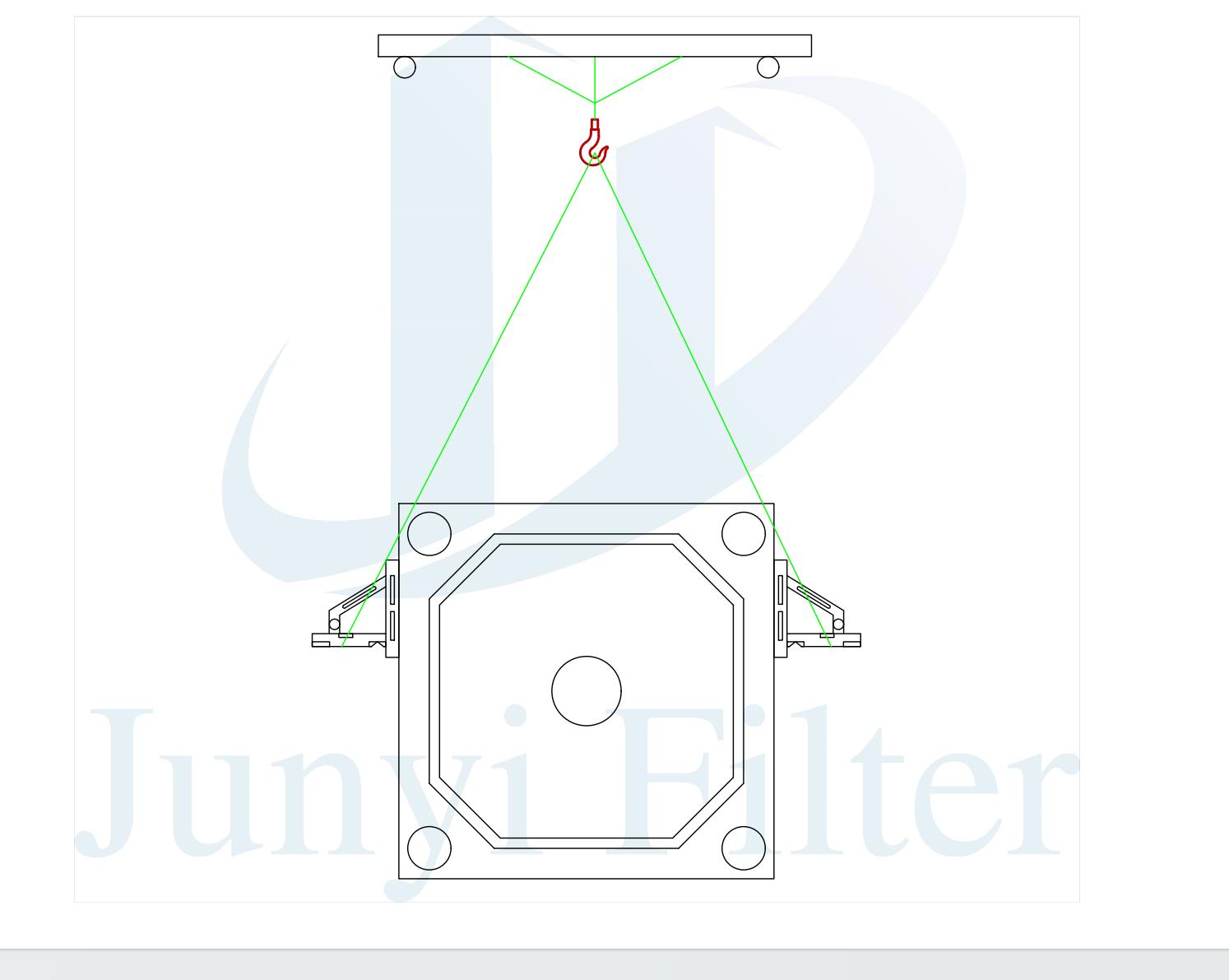

Umdwebo wohlelo lokuphakamisa ukucindezela kokuhlunga

✧Ukucaciswa Kokusebenza Kwesihlungi

1. Ngokwezidingo zenqubo yokwenza ukuxhunywa kwepayipi, nokwenza ukuhlolwa kokungena kwamanzi, ukubona ukucinana komoya kwepayipi;

2. Ukuze kuxhunywe ukunikezwa kwamandla okokufaka (isigaba se-3 + esingathathi hlangothi), kungcono ukusebenzisa ucingo oluphansi lwekhabhinethi yokulawula kagesi;

3. Ukuxhumana phakathi kwekhabhinethi yokulawula kanye nemishini ezungezile.Ezinye izintambo zixhunyiwe.Amatheminali omugqa okukhiphayo wekhabhinethi yokulawula alebulwe.Bheka umdwebo wesifunda ukuze uhlole izintambo bese uzixhuma.Uma kukhona ukuxega kutheminali engaguquki, cindezela futhi;

4. Gcwalisa i-hydraulic station ngamafutha angu-46 # hydraulic, uwoyela we-hydraulic kufanele ubonakale efasiteleni lokubuka ithangi.Uma umshini wokuhlunga usebenza ngokuqhubekayo amahora angu-240, buyisela noma hlunga uwoyela we-hydraulic;

5. Ukufakwa kwe-cylinder pressure gauge.Sebenzisa isikrufu ukugwema ukuzungezisa mathupha ngesikhathi sokufakwa.Sebenzisa i-O-ring ekuxhumaneni phakathi kwegeji yokucindezela kanye nesilinda samafutha;

6. Ngesikhathi sokuqala isilinda samafutha sisebenza, injini yesiteshi esisebenza ngaphansi kwamanzi kufanele ijikelezwe ngokwewashi (ikhonjiswe enjinini).Uma isilinda samafutha siphushelwa phambili, isisekelo segeji yokucindezela kufanele sikhiphe umoya, futhi isilinda samafutha kufanele siqhutshwe ngokuphindaphindiwe siye phambili nangemuva (ukucindezela komkhawulo ongaphezulu wegeji yokucindezela ngu-10Mpa) futhi umoya kufanele ukhululwe kanyekanye;

7. Umshini wokuhlunga usebenza okokuqala, khetha isimo semanyuwali sekhabhinethi yokulawula ukuze wenze imisebenzi ehlukene ngokulandelana;Ngemuva kokuthi imisebenzi ijwayelekile, ungakhetha isimo esizenzakalelayo;

8. Ukufakwa kwendwangu yokuhlunga.Ngesikhathi sokusebenza kwesilingo somshini wokuhlunga, ipuleti lokuhlunga kufanele lifakwe indwangu yokuhlunga kusengaphambili.Faka indwangu yokuhlunga epuleti lokuhlunga ukuze uqinisekise ukuthi indwangu yesihlungi isicaba futhi awekho ama-crease noma agqagqene.Phusha mathupha ipuleti lokuhlunga ukuze uqinisekise ukuthi indwangu yokuhlunga iyisicaba.

9. Ngesikhathi sokusebenza komshini wokuhlunga, uma kwenzeka ingozi, u-opharetha ucindezela inkinobho yokumisa izimo eziphuthumayo noma adonse intambo yezimo eziphuthumayo;