Umhlinzeki we-Automatic Filter Press

✧ Izici Zomkhiqizo

A,Ingcindezi yokuhlunga:0.6Mpa----1.0Mpa----1.3Mpa-----1.6mpa (ngokuzikhethela)

B,Izinga lokushisa lokuhlunga:45 ℃/ izinga lokushisa legumbi; 80℃/ izinga lokushisa eliphezulu; 100℃/ Izinga lokushisa eliphezulu.Isilinganiso sempahla eluhlaza yamapuleti okuhlunga okukhiqiza okushisa ahlukene akufani, futhi ubukhulu bamapuleti okuhlunga abufani.

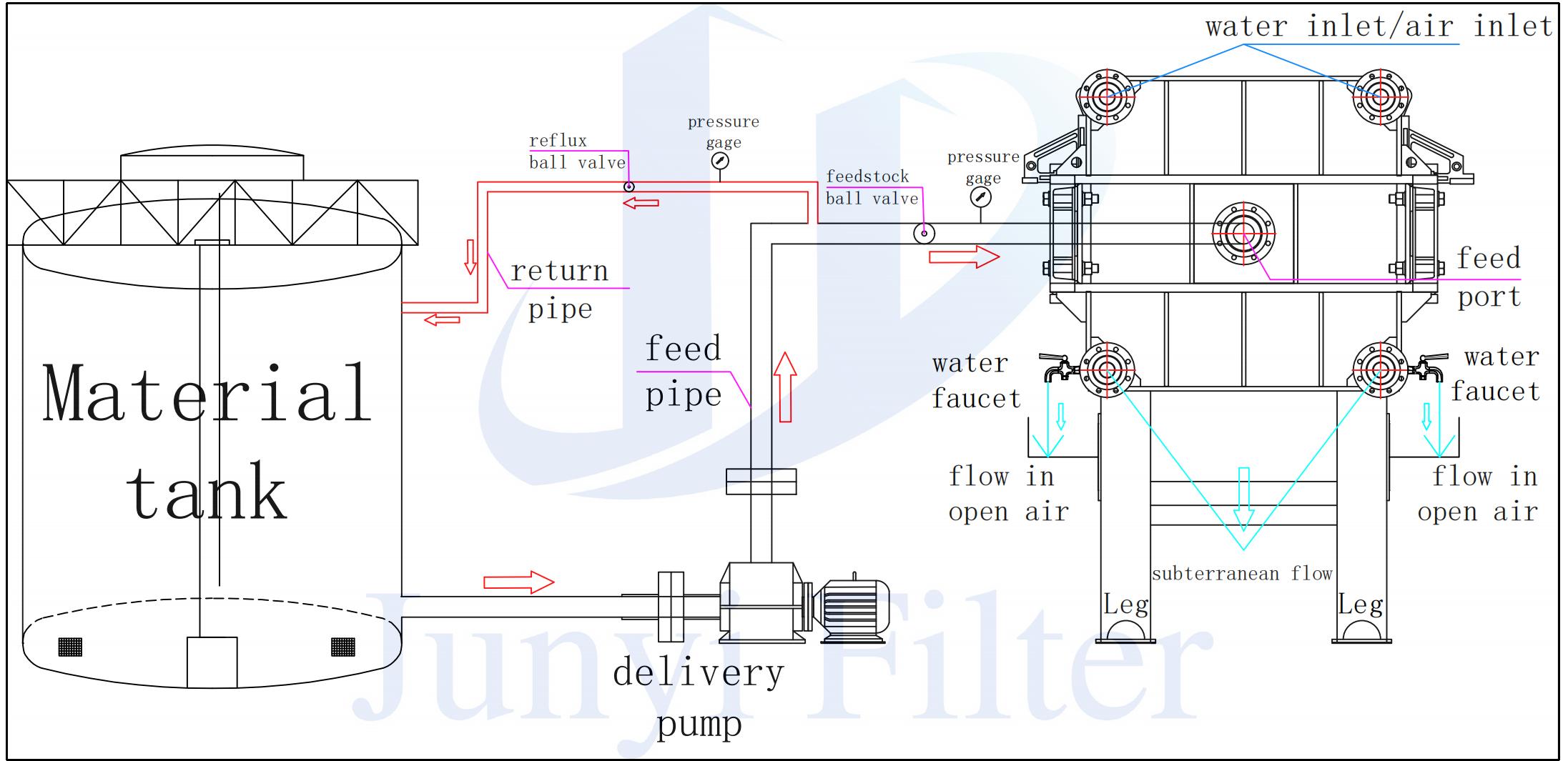

C-1Indlela yokukhipha - ukugeleza okuvulekile: Ompompi badinga ukufakwa ngaphansi kwezinhlangothi ezingakwesokunxele nezingakwesokudla zepuleti ngalinye lesihlungi, kanye nosinki ofanayo. Ukugeleza okuvulekile kusetshenziselwa uketshezi olungatholakali.

C-2Indlela yokukhipha uketshezi - clahlekelwaflow:Ngaphansi kwesiphetho sesiphakeli somshini wokuhlunga, kunamapayipi amakhulu amabili aseduze aphumayo, axhunywe nethangi lokutakula lokuhlunga. Uma uketshezi ludinga ukubuyiswa, noma uma uketshezi luguquguquka, lunuka, luvutha futhi luqhuma, ukugeleza okuseduze kungcono.

D-1,Ukukhethwa kwempahla yendwangu yokuhlunga: I-pH yoketshezi inquma impahla yendwangu yokuhlunga. I-PH1-5 iyindwangu yokuhlunga ye-polyester ene-acidic, i-PH8-14 iyindwangu yokuhlunga ye-alkaline polypropylene. I-viscous liquid noma eqinile ikhethwa ukukhetha indwangu yesihlungi se-twill, futhi uketshezi olungenayo i-viscous noma okuqinile kukhethwa indwangu yesihlungi esingenalutho.

D-2,Ukukhethwa kwemeshi yendwangu yokuhlunga: Uketshezi luyahlukaniswa, futhi inombolo yemeshi ehambisanayo ikhethwa osayizi abahlukene bezinhlayiyana eziqinile. Isihlungi se-mesh yendwangu ububanzi 100-1000 mesh. Ukuguqulwa kwe-Micron kuya kumanetha (1UM = 15,000 mesh---ngokombono).

E,Ukwelashwa kwe-rack surface:Uma u-PH yenanisela isisekelo se-asidi esimaphakathi noma esibuthakathaka, ingaphezulu lenduku yokucindezela isihlungi liqhunyiswa isihlabathi kuqala, bese lifafazwa ngopende wokuqala nowokuvikela ukugqwala. Uma inani le-PH liyi-asidi eqinile noma i-alkaline eqinile, indawo engaphezulu yozimele wokucindezela isihlungi iqhunyiswa ngesihlabathi, ifuthwe nge-primer, futhi isongwe ngensimbi engagqwali noma ipuleti le-PP.

F,Hlunga ukuwasha amakhekhe: Lapho izinto eziqinile zidinga ukubuyiswa, ikhekhe lokuhlunga line-asidi eqinile noma i-alkaline; Lapho ikhekhe lokuhlunga lidinga ukugezwa ngamanzi, sicela uthumele i-imeyili ukuze ubuze mayelana nendlela yokugeza.

G,Ukukhetha iphampu yokuphakela ukucindezela kokuhlunga:Isilinganiso se-solid-liquid, i-acidity, izinga lokushisa kanye nezici zoketshezi zihlukile, ngakho-ke amaphampu okuphakelayo ahlukene ayadingeka. Sicela uthumele i-imeyili ukuze ubuze.

✧ Inqubo Yokudla

✧ Izimboni Zokusebenza

Isetshenziswa kabanzi ekuhlukaniseni uketshezi oluqinile ku-petroleum, amakhemikhali, ama-dyestuff, i-metallurgy, ikhemisi, ukudla, ukuwasha amalahle, usawoti wezinto ezingaphili, utshwala, amakhemikhali, i-metallurgy, ikhemisi, imboni yokukhanya, amalahle, ukudla, izindwangu, ukuvikelwa kwemvelo, amandla nezinye izimboni.

✧ Imiyalo yoku-oda ye-Filter

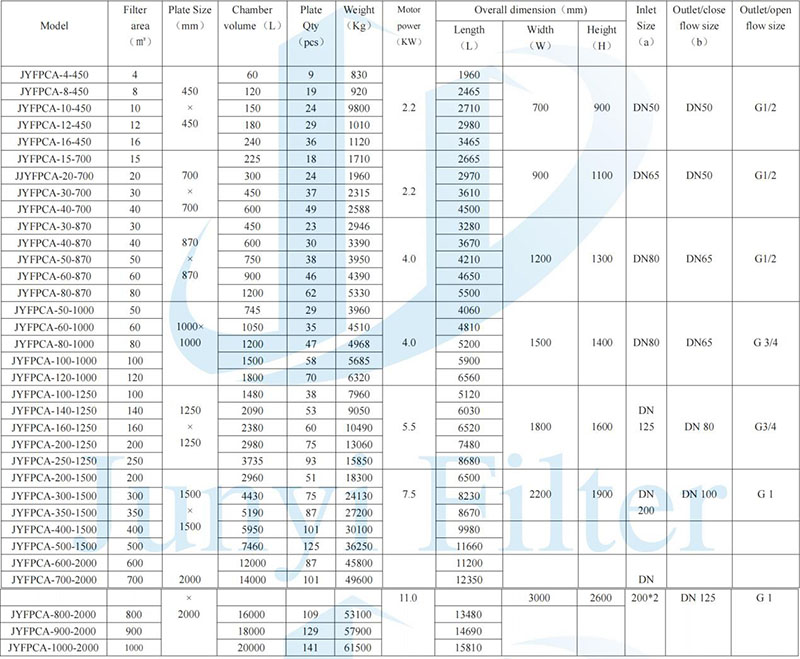

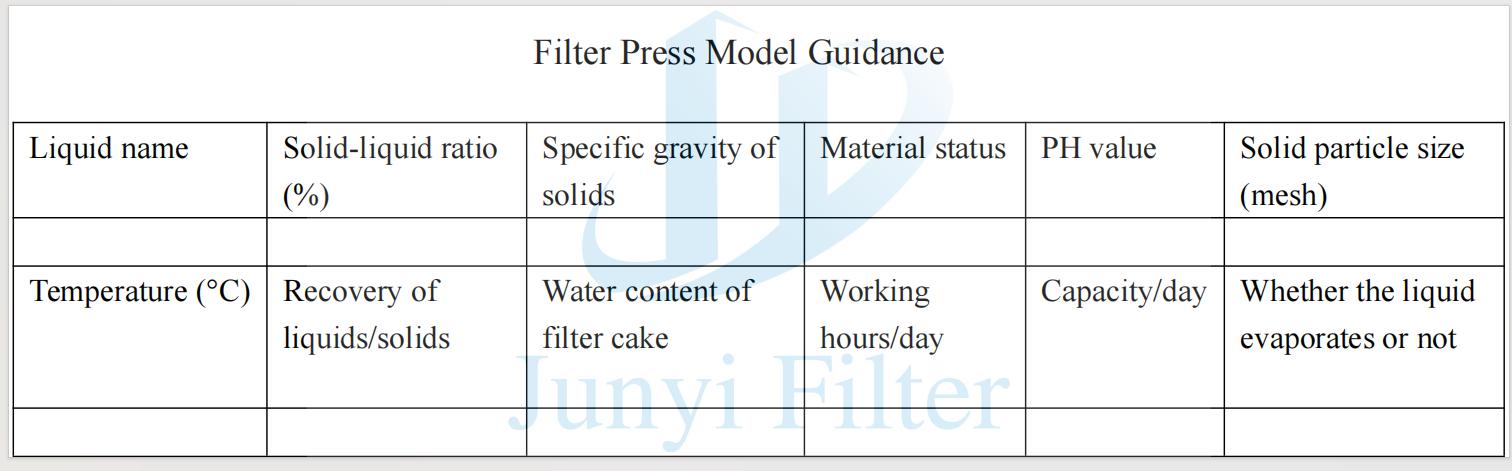

1. Bheka umhlahlandlela wokukhetha cindezela isihlungi, ukubuka konke cindezela isihlungi, imininingwane namamodeli, khethaimodeli nezinto ezisekelayo ngokwezidingo.

Isibonelo: Ukuthi ikhekhe lokuhlunga liyawashwa noma cha, noma ngabe isihlungi sivuliwe (ukugeleza okuboniwe) noma sivale (ukugeleza okungabonakali),ukuthi i-rack imelana nokugqwala noma cha, indlela yokusebenza, njll., kufanele icaciswe kuisivumelwano.

2. Ngokwezidingo ezikhethekile zamakhasimende, inkampani yethu ingaklama futhi ikhiqizeamamodeli angajwayelekile noma imikhiqizo eyenziwe ngokwezifiso.

3. Izithombe zomkhiqizo ezinikezwe kulo mbhalo ngezereferensi kuphela. Uma kwenzeka izinguquko, thinangeke inikeze noma yisiphi isaziso futhi umyalo wangempela uzosebenza.

✧ Izidingo zokusetshenziswa komshini wokuhlunga

1. Ngokwezidingo zenqubo yokwenza ukuxhunywa kwepayipi, nokwenza ukuhlolwa kokungena kwamanzi, ukubona ukucinana komoya kwepayipi;

2. Ukuze kuxhunywe ukunikezwa kwamandla okokufaka (isigaba se-3 + esingathathi hlangothi), kungcono ukusebenzisa ucingo oluphansi lwekhabhinethi yokulawula kagesi;

3. Ukuxhumana phakathi kwekhabhinethi yokulawula kanye nemishini ezungezile. Ezinye izintambo zixhunyiwe. Amatheminali omugqa okukhiphayo wekhabhinethi yokulawula alebulwe. Bheka umdwebo wesifunda ukuze uhlole izintambo bese uzixhuma. Uma kukhona ukuxega kutheminali engaguquki, cindezela futhi;

4. Gcwalisa isiteshi se-hydraulic ngamafutha angu-46 # hydraulic, uwoyela we-hydraulic kufanele ubonakale efasiteleni lokubuka ithangi. Uma umshini wokuhlunga usebenza ngokuqhubekayo amahora angu-240, buyisela noma hlunga uwoyela we-hydraulic;

5. Ukufakwa kwe-cylinder pressure gauge. Sebenzisa isikrufu ukugwema ukuzungezisa mathupha ngesikhathi sokufakwa. Sebenzisa i-O-ring ekuxhumaneni phakathi kwegeji yokucindezela kanye nesilinda samafutha;

6. Isikhathi sokuqala lapho isilinda samafutha sisebenza, injini yesiteshi esisebenza ngaphansi kwamanzi kufanele ijikelezwe ngokwewashi (ikhonjiswe enjinini). Uma isilinda samafutha siphushelwa phambili, isisekelo segeji yokucindezela kufanele sikhiphe umoya, futhi isilinda samafutha kufanele siphushwe ngokuphindaphindiwe siye phambili nangemuva (ukucindezela komkhawulo ongaphezulu wegeji yokucindezela ngu-10Mpa) futhi umoya kufanele ukhishwe kanyekanye;

7. Umshini wokuhlunga usebenza okokuqala, khetha isimo semanyuwali sekhabhinethi yokulawula ukuze wenze imisebenzi ehlukene ngokulandelana; Ngemuva kokuthi imisebenzi ijwayelekile, ungakhetha isimo esizenzakalelayo;

8. Ukufakwa kwendwangu yokuhlunga. Ngesikhathi sokusebenza kwesilingo somshini wokuhlunga, ipuleti lokuhlunga kufanele lifakwe indwangu yokuhlunga kusengaphambili. Faka indwangu yokuhlunga epuleti lokuhlunga ukuze uqinisekise ukuthi indwangu yesihlungi isicaba futhi awekho ama-crease noma agqagqene. Phusha mathupha ipuleti lokuhlunga ukuze uqinisekise ukuthi indwangu yokuhlunga iyisicaba.

9. Ngesikhathi sokusebenza komshini wokuhlunga, uma kwenzeka ingozi, u-opharetha ucindezela inkinobho yokumisa izimo eziphuthumayo noma adonse intambo yezimo eziphuthumayo;

✧Amaphutha amakhulu nezindlela zokuxazulula izinkinga

| Iphutha elenzeka | Iphutha Isimiso | Ukuxazulula inkinga |

| Umsindo omkhulu noma ingcindezi engazinzile ohlelweni lwe-hydraulic | 1, Iphampu kawoyela ayinalutho noma ipayipi lokumunca uwoyela livaliwe. | Ukugcwalisa ithangi likawoyela, xazulula ukuvuza kwepayipi lokumunca |

| 2, Indawo yokuvala yesihlungi ibanjwa nge-misc. | Hlanza izindawo zokuvala | |

| 3, Umoya kumjikelezo kawoyela | Khipha umoya | |

| 4, Iphampu kawoyela ilimele noma igugile | Faka esikhundleni noma lungisa | |

| 5, I-valve yokusiza ayizinzile | Faka esikhundleni noma lungisa | |

| 6, Ukudlidliza kwepayipi | Ukuqinisa noma ukuqinisa | |

| Ingcindezi enganele noma engekho ohlelweni lwe-hydraulic | 1, Ukulimala kwepompo kawoyela | Faka esikhundleni noma lungisa |

| ukulungisa kabusha | |

| 3, I-viscosity kawoyela iphansi kakhulu | Ukushintshwa kwamafutha | |

| 4, Kukhona ukuvuza ohlelweni lwephampu kawoyela | Lungisa ngemva kokuhlolwa | |

| Ingcindezi yesilinda enganele ngesikhathi sokucindezela | 1, I-valve yokusiza ingcindezi ephezulu eyonakele noma ebambelele | Faka esikhundleni noma lungisa |

| 2. I-valve yokuhlehlisa eyonakele | Faka esikhundleni noma lungisa | |

| 3. I-piston seal enkulu eyonakele | esikhundleni | |

| 4, piston encane elimele "0" uphawu | esikhundleni | |

| 5. Iphampu kawoyela eyonakele | Faka esikhundleni noma lungisa | |

| 6, Ukucindezela kulungiswe ngokungalungile | lungisa kabusha | |

| Ingcindezi yesilinda enganele uma ubuya | 1, I-valve yokusiza ingcindezi ephansi eyonakele noma enamathele | Faka esikhundleni noma lungisa |

| 2. I-piston seal encane eyonakele | esikhundleni | |

| 3, piston encane elimele "0" uphawu | esikhundleni | |

| I-piston igaqa | Umoya kumjikelezo kawoyela | Faka esikhundleni noma lungisa |

| Umsindo wokudlulisa omkhulu | 1, Ukuthwala umonakalo | esikhundleni |

| 2. Igiya lishaya noma ligqoke | Faka esikhundleni noma lungisa | |

| Ukuvuza okukhulu phakathi kwamapuleti namafreyimu |

| esikhundleni |

| 2. Imfucumfucu endaweni evaliwe | Hlanza | |

| 3, Indwangu yokuhlunga enemigoqo, ukugqagqana, njll. | Ifanelekele ukuqedwa noma ukushintshwa | |

| 4. Amandla okucindezela anganele | Ukwenyuka okufanele kwamandla okucindezela | |

| Ipuleti nohlaka kuphukile noma kukhubazekile | 1, Ingcindezi yokuhlunga iphezulu kakhulu | yehlisa ingcindezi |

| 2, Izinga lokushisa eliphezulu | Amazinga okushisa ehliswe ngokufanelekile | |

| 3. Amandla okucindezela aphezulu kakhulu | Lungisa amandla okucindezela ngendlela efanele | |

| 4, Ukuhlunga ngokushesha kakhulu | Izinga lokuhlunga elincishisiwe | |

| 5. Imbobo yokuphakelayo evalekile | Ukuhlanza imbobo yokuphakelayo | |

| 6, Ukuma phakathi kokuhlunga | Ungayeki phakathi kokuhlunga | |

| Isistimu yokugcwalisa isebenza kaningi | 1, I-valve yokuhlola i-hydraulic control ayivalwanga ngokuqinile | esikhundleni |

| 2. Ukuvuza kusilinda | Ukushintshwa kwama-cylinder seal | |

| Ukuhluleka kwe-valve yokuhlehlisa i-hydraulic | I-Spool ibanjiwe noma ilimele | Hlukanisa futhi uhlanze noma ubuyisele i-valve eqondisayo |

| I-trolley ayikwazi ukuhlehliswa ngenxa yomthelela emuva naphambili. | I-1, ingcindezi yesifunda kawoyela ephansi kawoyela | lungisa |

| 2, Ingcindezi edluliselwe ingcindezi iphansi | lungisa | |

| Ukwehluleka ukulandela izinqubo | Ukuhluleka kwengxenye yesistimu ye-hydraulic, uhlelo lukagesi | Lungisa noma shintsha ngokuphawulekayo ngemva kokuhlolwa |

| Ukulimala kwe-diaphragm | 1, umfutho womoya onganele | Ukucindezela kwabezindaba okwehlisiwe |

| 2、Isiphakeli esinganele | Ukucindezela ngemva kokugcwalisa igumbi ngezinto | |

| 3, Into yangaphandle ibhoboze i-diaphragm. | ukususwa kwezindaba zangaphandle | |

| Ukulimala kokugoba kugongolo oluyinhloko | 1, Izisekelo ezimbi noma ezingalingani | Lungisa kabusha noma wenze futhi |