A isihlungi esizihlanzayoiyidivayisi enembayo evimba ngokuqondile ukungcola emanzini isebenzisa isikrini sokuhlunga. Ikhipha okuqinile okumisiwe nezinhlayiya emanzini, inciphisa ukuthuthumela, ihlanze ikhwalithi yamanzi, futhi inciphise ukwakheka kokungcola, ulwelwe, nokugqwala ohlelweni. Lokhu kusiza ukuhlanza amanzi nokuqinisekisa ukusebenza okuvamile kwezinye izinto zokusebenza ohlelweni.

Ingxenye 1: Isimiso Sokusebenza

Inqubo yokuhlunga: Amanzi azohlungwa angena esihlungini nge-inlet yamanzi futhi ageleze esikrinini sokuhlunga. Usayizi wembotshana wesikrini sokuhlunga unquma ukunemba kokuhlunga. Ukungcola kugcinwa ngaphakathi kwesikrini sokuhlunga, kuyilapho amanzi ahlungiwe edlula esikrinini sokuhlunga futhi engena endaweni yokukhipha amanzi, bese egeleza emanzini - esebenzisa imishini noma uhlelo lokwelapha olulandelayo. Phakathi

- inqubo yokuhlunga, njengoba ukungcola kunqwabelana ngokuqhubekayo ebusweni besikrini sokuhlunga, umehluko othile wengcindezi uzokwakheka phakathi kwezinhlangothi zangaphakathi nezingaphandle zesikrini sokuhlunga.

- Ukuhlanza Inqubo: Uma umehluko wengcindezi ufinyelela inani elibekiwe noma isikhawu sesikhathi sokuhlanza esimisiwe sifinyelelwa, isihlungi sokuhlanza ngokwakho sizoqala ngokuzenzakalelayo uhlelo lokuhlanza. Ibhulashi noma i-scraper ishayelwa injini ukuze ijikeleze futhi ikhuhle ingaphezulu lesikrini sokuhlunga. Ukungcola okunanyathiselwe esikrinini sokuhlunga kuyasuswa bese kugudluzwa ngasemseleni wokukhuculula indle ngokugeleza kwamanzi ukuze akhishwe. Phakathi nenqubo yokuhlanza, asikho isidingo sokuphazamisa ukusebenza kwesistimu, ukufeza ukuhlanzwa kwe-intanethi ngaphandle kokuphazamisa ukusebenza okuvamile kwesistimu yokuhlunga.

Nakuba izakhiwo ezithile nezindlela zokusebenza zokuzihlanza izihlungi zezinhlobo ezahlukene kanye nemikhiqizo zingase zihluke, isimiso esiyisisekelo siwukubamba ukungcola ngesikrini sokuhlunga bese usebenzisa idivayisi yokuhlanza okuzenzakalelayo ukuze ususe njalo ukungcola esikrinini sokuhlunga, ukuqinisekisa umphumela wokuhlunga kanye namandla okugeleza kwamanzi kwesihlungi.

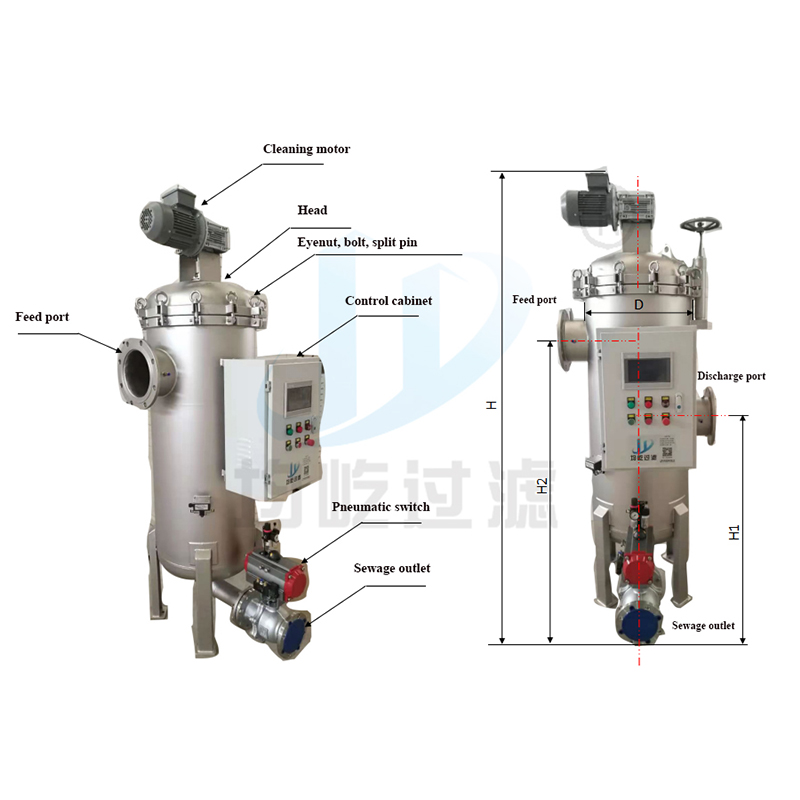

Ingxenye 2: Izingxenye Eziyinhloko

- Isikrini sesihlungi: Izinto ezivamile zihlanganisa insimbi engagqwali nenayiloni. Izikrini zokuhlunga zensimbi engagqwali zibonakala ngamandla amakhulu nokumelana nokugqwala, ezifanele izimfanelo zamanzi ezihlukahlukene kanye nezindawo zokusebenza. Izikrini zokuhlunga inayiloni zithambile futhi zinokunemba okuphezulu kokuhlunga, okuvame ukusetshenziselwa ukuhlunga izinhlayiya ezinhle.

- Izindlu: Ngokuvamile zenziwe ngezinto ezifana nensimbi engagqwali. Izindlu zensimbi engagqwali zinamandla amakhulu nokumelana nokugqwala, okungavumelana nezimfanelo zamanzi ezihlukene nezimo zokusebenza.

- Idivayisi Yezimoto Nokushayela: Ngesikhathi sokuhlanza okuzenzakalelayo, idivayisi ye-motor kanye nokushayela inikeza amandla ezingxenyeni zokuhlanza (njengamabhulashi nama-scrapers), okubenza bakwazi ukuhlanza ngokuphumelelayo isikrini sokuhlunga.

- I-Pressure Difference Controller: Ihlola ngokuqhubekayo umehluko wengcindezi phakathi kwezinhlangothi zangaphakathi nangaphandle zesikrini sokuhlunga futhi ilawula ukuqala kohlelo lokuhlanza ngokusho komkhawulo wokuhluka kwengcindezi ebekiwe. Lapho umehluko wengcindezi ufinyelela inani elibekiwe, libonisa ukuthi kunenani elikhulu lokuqoqwa kokungcola ebusweni besikrini sokuhlunga, futhi ukuhlanza kuyadingeka. Ngalesi sikhathi, isilawuli somehluko wengcindezi sizothumela isignali ukuqalisa idivayisi yokuhlanza.

- I-Wage Valve: Phakathi nenqubo yokuhlanza, i-valve ye-sewage ivuliwe ukuze kukhishwe ukungcola okuhlanjululwe kusihlungi. Ukuvulwa nokuvalwa kwe-valve ye-sewage kulawulwa ngokuzenzakalelayo yisistimu yokulawula ukuze kuqinisekiswe ukuqhubeka kahle kwenqubo yokuhlanza.

- Izingxenye Zokuhlanza (Amabhulashi, Ama-Scrapers, njll.): Ukuklanywa kwezingxenye zokuhlanza kudinga ukucabangela ukuhambisana nesikrini sokuhlunga ukuze kuqinisekiswe ukuthi ukungcola kwesikrini sokuhlunga kungasuswa ngokuphumelelayo ngaphandle kokulimaza isikrini sokuhlunga.

- Isistimu yokulawula ye-PLC: Ilawula futhi ilawule ukusebenza kwayo yonke isihlungi sokuhlanza ngokwakho, okubandakanya ukuqapha umehluko wengcindezi, ukulawula ukuqala nokuma kwe-motor, nokuvulwa nokuvalwa kwe-valve ye-sewage. Uhlelo lokulawula lungaqedela ngokuzenzakalelayo ukuhlunga nokuhlanza izinqubo ngokuya ngohlelo olusethiwe, futhi lungase lungenelele ngesandla.

- Ingxenye 3: Izinzuzo

- Izinga eliphakeme le-Automation: Isihlungi sokuhlanza singakwazi ukuqala ngokuzenzakalelayo uhlelo lokuhlanza ngokusho komehluko wengcindezi ebekiwe noma isikhawu sesikhathi, ngaphandle kwesidingo sokusebenza okwenziwa ngesandla njalo. Isibonelo, ezinhlelweni zamanzi ezijikelezayo ezimbonini, zingasebenza ngokuqhubekayo nangokuzinza, zehlise kakhulu izindleko zabasebenzi kanye nokuqina kokulungiswa kwezandla.

Ukuhlunga Okuqhubekayo: Asikho isidingo sokuphazamisa ukusebenza kwesistimu phakathi nenqubo yokuhlanza, ukufeza ukuhlanza ku-inthanethi. Ngokwesibonelo, ekuhlungeni

- ingxenye yesikhungo sokuhlanza indle, ingaqinisekisa ukuthi indle idlula ngesihlungi ngaphandle kokuphazamiseka, ngaphandle kokuphazamisa ukuqhubeka kwayo yonke inqubo yokwelapha kanye nokwenza ngcono ukusebenza kahle kokukhiqiza.

- Ukunemba Okuphezulu Kokuhlunga: Isikrini sokuhlunga sinezincazelo ezihlukahlukene zosayizi wembotshana, ezingahlangabezana nezidingo ezihlukile zokunemba kokuhlunga. Ekulungiseni amanzi e-ultrapure embonini ye-electronics, angasusa ngempumelelo ukungcola okuncane futhi aqinisekise ukuhlanzeka okuphezulu kwekhwalithi yamanzi.

- Impilo Emide Yenkonzo: Ngenxa yomsebenzi wokuhlanza okuzenzakalelayo, ukuvinjelwa kanye nokulimala kwesikrini sokuhlunga kuyancishiswa, ukwandisa impilo yesevisi yesikrini sokuhlunga kanye nesihlungi sonke. Ngokuvamile, ngokulungiswa okufanele, impilo yesevisi yesihlungi sokuhlanza singafinyelela iminyaka engaphezu kwe-10.

- Ibanga Lohlelo Olubanzi: Ifanele ukuhlunga uketshezi ezimbonini ezihlukahlukene nezinhlobo ezahlukene, njengokuhlunga uketshezi ezimbonini ezifana namakhemikhali, amandla, ukudla nesiphuzo, kanye nokuhlunga kwamanzi ezinhlelweni zokunisela.

Isikhathi sokuthumela: Mar-14-2025