I-PP Chamber Filter Plate

✧ Incazelo

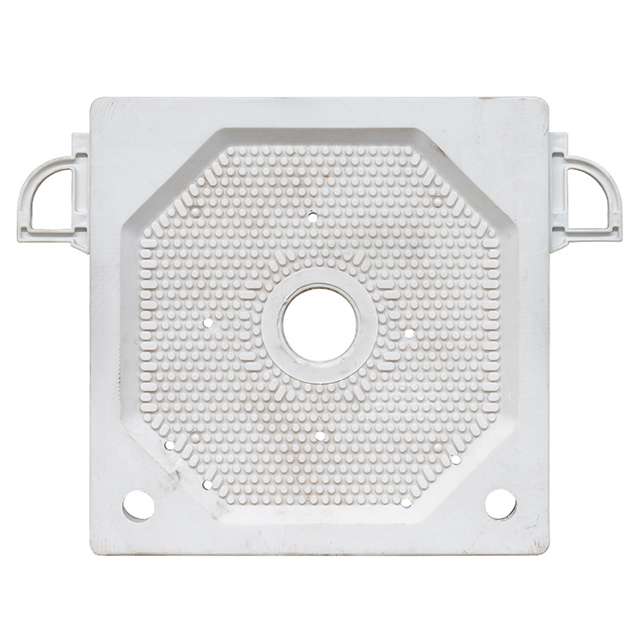

I-Filter Plate iyingxenye ebalulekile yokucindezela isihlungi. Isetshenziselwa ukusekela indwangu yokuhlunga futhi igcine amakhekhe asindayo okuhlunga. Izinga lepuleti lokuhlunga (ikakhulukazi flatness kanye nokunemba kwepuleti lokuhlunga) lihlobene ngokuqondile nomphumela wokuhlunga kanye nempilo yesevisi.

Izinto ezihlukile, amamodeli nezimfanelo zizothinta ukusebenza kokuhlunga kwawo wonke umshini ngokuqondile. Imbobo yayo yokudla, ukusabalalisa amaphuzu okuhlunga (isiteshi sokuhlunga) kanye neziteshi zokukhipha i-filtrate zinemiklamo ehlukene ngokusho kwezinto ezahlukene.

| Impahla yamapuleti okuhlunga | Ipuleti le-PP, ipuleti le-membrane, ipuleti lokuhlunga lensimbi, ipuleti lesihlungi lensimbi engagqwali. |

| Ifomu lokudla | Ukondla okuphakathi, ukuphakela ekhoneni, ukudla okuphakathi nendawo, njll. |

| Indlela yokukhishwa kwe-filtrate | Ukugeleza okubonakalayo, ukugeleza okungabonakali. |

| Uhlobo lwepuleti | Ipuleti lesihlungi se-Plate-frame, ipuleti lesihlungi segumbi, ipuleti lesihlungi se-membrane, ipuleti lesihlungi eline-recessed, ipuleti lesihlungi esiyindilinga. |

✧ Izici Zomkhiqizo

I-Polypropylene (PP), eyaziwa nangokuthi i-polypropylene ephakeme yamangqamuzana. Le nto inokumelana okuhle kakhulu nama-acids ahlukahlukene kanye ne-alkali, kufaka phakathi i-asidi eqinile ye-hydrofluoric acid. Inokuqina okuqinile nokuqina, ithuthukisa ukusebenza kokuvalwa kokucindezelwa. Ifanele ukucindezela kokuhlunga.

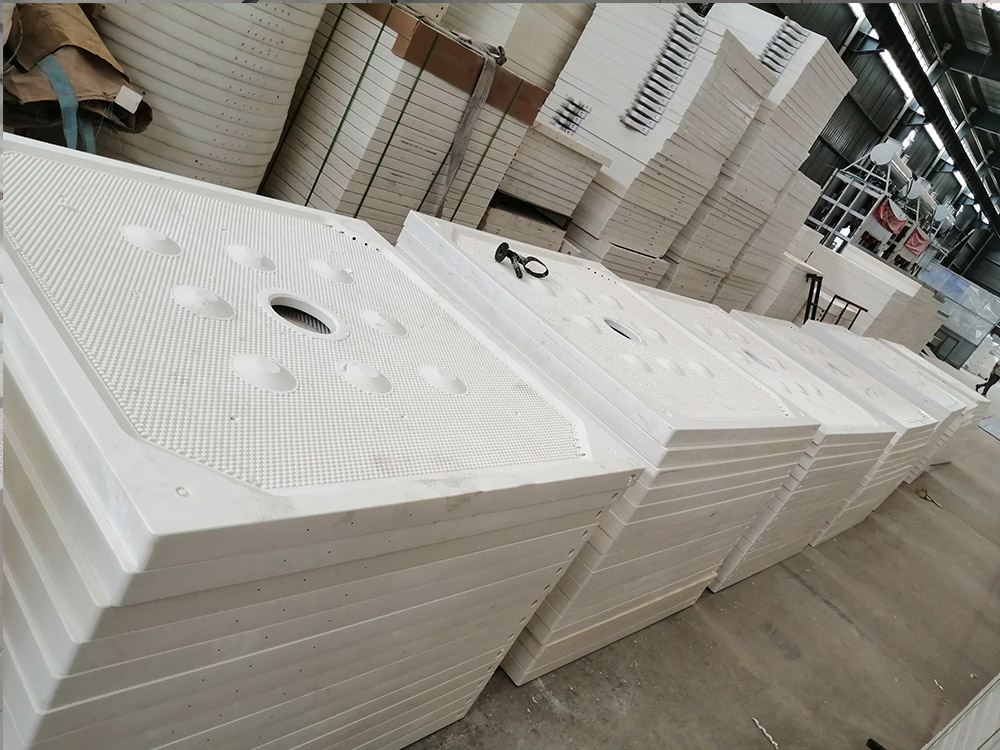

1. I-polypropylene eguquliwe futhi eqinisiwe enefomula ekhethekile, ebunjwe ngesikhathi esisodwa.

2. Ukucubungula okukhethekile kwemishini ye-CNC, enendawo eyisicaba kanye nokusebenza okuhle kokuvala.

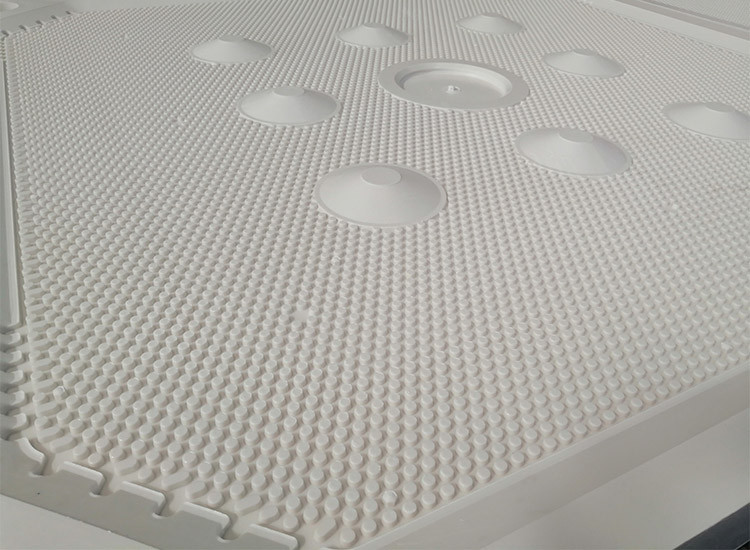

3. Isakhiwo sepuleti lesihlungi samukela umklamo oguquguqukayo we-cross-section, ngesakhiwo samachashazi ayi-conical esatshalaliswa ngesimo se-plum blossom engxenyeni yokuhlunga, ngokuphumelelayo ukunciphisa ukumelana nokuhlunga kwezinto;

4. Ijubane lokuhlunga liyashesha, ukuklanywa kwesiteshi sokugeleza kwe-filtrate kunengqondo, futhi ukuphuma kwe-filtrate kubushelelezi, kuthuthukisa kakhulu ukusebenza kahle kokusebenza kanye nezinzuzo zezomnotho zomshini wokuhlunga.

5. Ipuleti lokuhlunga le-polypropylene eliqinisiwe nalo linezinzuzo ezinjengamandla aphezulu, isisindo esilula, ukumelana nokugqwala, i-asidi, ukumelana ne-alkali, okungewona ubuthi, nokungabi naphunga.

✧ Izimboni Zokusebenza

Ipuleti yokuhlunga inokuguquguquka okuqinile kanye nekhwalithi yomkhiqizo omuhle kakhulu, futhi isetshenziswa kabanzi emikhakheni efana nemboni yamakhemikhali, imboni yokukhanya, i-petroleum, imithi, ukudla, ukuthuthukiswa kwezinsiza, i-metallurgy namalahle, imboni yezokuvikela kazwelonke, ukuvikelwa kwemvelo, njll.

✧ Ipharamitha yePleti lokuhlunga

| Imodeli(mm) | PP Camber | I-diaphragm | Kuvaliwe | Insimbi engagqwali | Insimbi | PP Uhlaka kanye Plate | Umbuthano |

| 250×250 | √ | ||||||

| 380×380 | √ | √ | √ | √ | |||

| 500×500 | √ | √ | √ | √ | √ | ||

| 630×630 | √ | √ | √ | √ | √ | √ | √ |

| 700×700 | √ | √ | √ | √ | √ | √ | |

| 800×800 | √ | √ | √ | √ | √ | √ | √ |

| 870×870 | √ | √ | √ | √ | √ | √ | |

| 900×900 | √ | √ | √ | √ | √ | √ | |

| 1000×1000 | √ | √ | √ | √ | √ | √ | √ |

| 1250×1250 | √ | √ | √ | √ | √ | √ | |

| 1500×1500 | √ | √ | √ | √ | |||

| 2000×2000 | √ | √ | √ | ||||

| Izinga lokushisa | 0-100 ℃ | 0-100 ℃ | 0-100 ℃ | 0-200 ℃ | 0-200 ℃ | 0-80℃ | 0-100 ℃ |

| Ingcindezi | 0.6-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.0Mpa | 0-0.6Mpa | 0-2.5Mpa |

| Hlunga Uhlu Lwepharamitha Yeplate | |||||||

| Imodeli(mm) | PP Camber | I-diaphragm | Kuvaliwe | Ingenabalainsimbi | Insimbi | PP Uhlakakanye nePlate | Umbuthano |

| 250×250 | √ | ||||||

| 380×380 | √ | √ | √ | √ | |||

| 500×500 | √ | √ | √ | √ | √ | ||

| 630×630 | √ | √ | √ | √ | √ | √ | √ |

| 700×700 | √ | √ | √ | √ | √ | √ | |

| 800×800 | √ | √ | √ | √ | √ | √ | √ |

| 870×870 | √ | √ | √ | √ | √ | √ | |

| 900×900 | √ | √ | √ | √ | √ | √ | |

| 1000×1000 | √ | √ | √ | √ | √ | √ | √ |

| 1250×1250 | √ | √ | √ | √ | √ | √ | |

| 1500×1500 | √ | √ | √ | √ | |||

| 2000×2000 | √ | √ | √ | ||||

| Izinga lokushisa | 0-100 ℃ | 0-100 ℃ | 0-100 ℃ | 0-200 ℃ | 0-200 ℃ | 0-80℃ | 0-100 ℃ |

| Ingcindezi | 0.6-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.6Mpa | 0-1.0Mpa | 0-0.6Mpa | 0-2.5Mpa |